Maintaining Dam Safety with Maxitool Australia

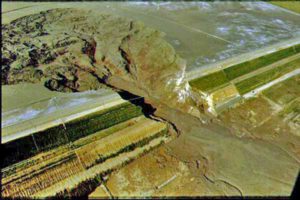

Potential process dam failures have become a focal point of the mining industry following the devastating tailings dam collapse at Brazil’s Brumadinho iron ore mine. This incident and other domestic failures have sparked scrutiny of the possible risks and consequences to tailings storage facilities in Australia. Many mining companies have begun to conduct self-audits to identify potential hazards within their facilities.

Dams can pose a risk of failure when their structures are subjected to excessive physical pressure from liquid and solid products. Since the solid product is heavier than water, a dam full of solids will apply considerably greater pressure to its structure than if filled with water.

In addition to the risk to public safety, process dam failures can have irreversible environmental impact due to high levels of heavy metals, silt, chemicals or radiation. Dredging the solids from a dam or reservoir can significantly reduce the amount of physical stress on a dam and remove the bulk of any environmental contaminants that it may hold.

Even if a dam does not pose a risk of failure, there are several advantages to removing the solid product. These include, but are not limited to:

- Restoring water storage capacity.

- Reprocessing tailings to extract any remaining product.

- Reducing the risk of silt run-off due to weather events.

Dredging works can be performed as a one-off or periodically as part of an effective proactive maintenance strategy.